In a complex piping system, there is a small role that is often overlooked. It is neither responsible for circulation nor for connection, but it usually determines the integrity and safety of the entire system - this is the PVC plug.

Many people think that pipe plugs are just small things that "plug the hole". However, if the wrong type, specifications, or scenarios are used, not only will the sealing effect not be achieved, but it may also cause chain problems such as leakage, seepage pressure, and equipment damage. Therefore, don't underestimate this small PVC plug. The science of its selection is not simple at all.

PVC plugs of different structures serve different needs. When choosing, you must first confirm the design and functional positioning of your system to avoid unnecessary trouble.

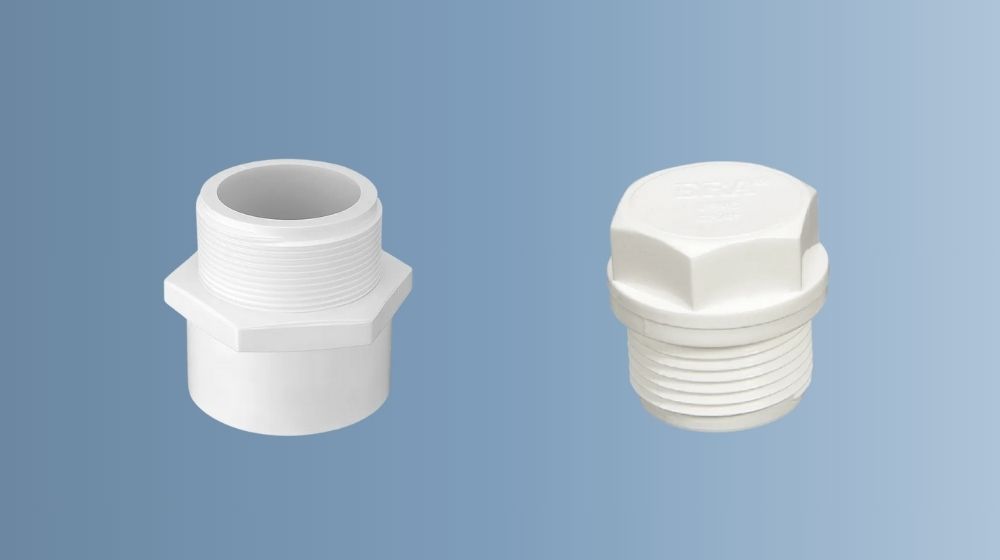

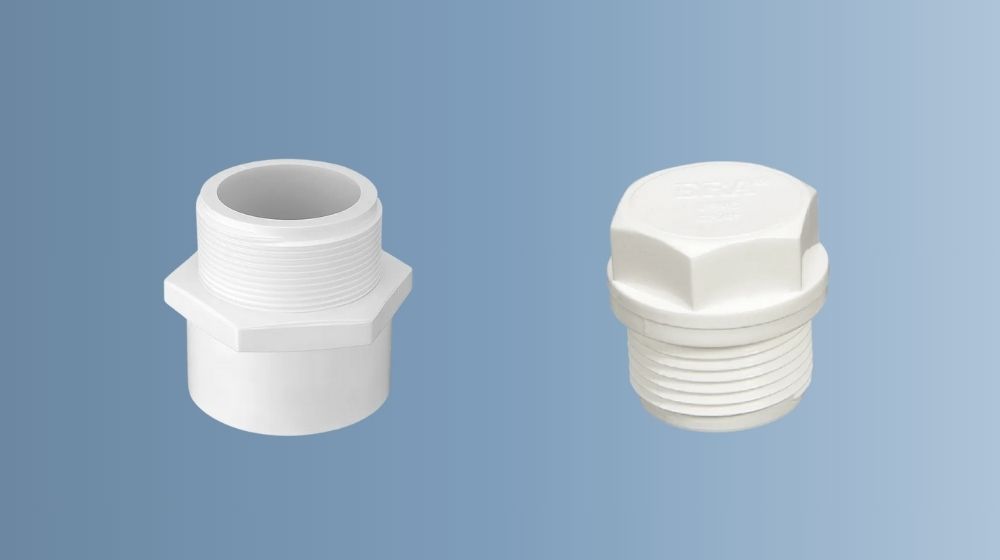

It is the most common type of PVC plug, which is usually inserted directly into the PVC pipe and maintains the sealing effect through friction or a sealing ring.

This type of PVC plug is suitable for scenarios where the pressure is not high and can be replaced regularly, such as the tail end of agricultural drip irrigation systems and household drainage systems.

It achieves a sealing effect by rotating and tightening, providing stronger sealing and pressure resistance. This is commonly used in industrial scenarios or systems that need to be repaired, and is easy to disassemble and reuse.

This type of PVC plug is inserted into the pipe during installation, and then expands, bites, and locks in place through the side structure to achieve a tight seal. It is very suitable for irregular pipe openings or working conditions that require vibration and anti-slip, and is commonly used in equipment maintenance, port sealing.

Choose the corresponding plug fitting according to the shape of the pipe section.

Round shapes are commonly used in PVC water pipe systems, while square shapes are found in special-shaped pipes such as mechanical parts and furniture frames.

In addition to the differences in appearance, PVC plugs with different structures also have significant differences in function.

Insertable PVC plugs are fixed by friction, so they are only suitable for low-pressure pipelines, such as non-pressure drainage systems.

Threaded and expansion plugs enhance the bite force through the mechanical indentation principle, so they have good water pressure resistance and are suitable for water pumps or closed systems with back pressure. They can remain stable and not fall off in high-pressure environments.

Insertion-type plugs are low-cost but cannot be reused. They are disposable products and are prone to damaging the sealing edge once removed.

Threaded and expansion-type plugs are not only convenient for rotation and loading, and unloading, but also are not easy to deform after repeated use. They are suitable for scenarios that require reversible operations, such as periodic inspections and equipment maintenance, which can improve maintenance efficiency and economy.

In the fields of furniture manufacturing, architectural decoration, etc., PVC plugs often need to play the role of beautifying the seal.

At this time, you need to choose a plug with rounded edges, fitting size, and smooth surface treatment. This plug not only covers the burrs, but also adds to the overall texture.

The selection of a PVC plug is by no means universal, but needs to be matched according to the specific application scenario.

The system usually requires good sealing, easy installation and easy replacement, so it is recommended to use a plug-in or internal thread PVC plug, which is often used in washing machine drain pipes, household water meter closures and other scenarios to ensure hygiene and safety.

It is recommended to use the insertion-type plug as the main one and the threaded-type plug as the auxiliary one. Because the requirements of this system are usually low cost, large quantity, and fast sealing.

The insertion type is very suitable for temporary closure or seasonal adjustment. If it involves zoned irrigation or needs to be disassembled regularly, the threaded type is better.

This type of system has high requirements and requires high sealing, anti-pollution and impact resistance. It is recommended to use expansion or threaded PVC plugs for systems such as oil drums and liquid storage tanks to avoid leakage or contamination risks during transportation.

They are usually found in furniture that requires smooth edges, scratch resistance, and good aesthetics. They are mostly beautiful, plug-in round plugs. These plugs are mostly used for metal or PVC frame sealing, display stand foot pads, anti-slip blocking, etc., which not only protect the structure but also add visual neatness.

Although the PVC plug is small, it carries important functions such as sealing, safety, and maintenance of the pipeline system. If the selection is inappropriate, it will not only affect the user experience but also bring systemic risks.

Therefore, understanding common selection errors and potential consequences is crucial to avoid losses and improve system stability.

If the plug does not match the pipe interface and lacks an effective bite or sealing structure, it is very easy to slip off due to vibration, water pressure fluctuations, or external pulling during use.

Once it falls off, liquids and gases may leak, and rainwater, insects, rodents, and other debris may enter from the pipe opening, causing pipeline pollution, equipment damage, and even system shutdown.

Some users choose to force plugs slightly larger than the pipe diameter to ensure "firmness", ignoring the expansion characteristics of the material.

This approach may be effective in the short term, but long-term use will cause the pipe mouth to deform, and even cracks to appear when there is thermal expansion and contraction or changes in internal pressure. In severe cases, it will also affect the sealing and pressure-bearing capacity of the entire pipeline.

Many PVC plugs have not been treated for high temperature resistance and are prone to softening and swelling in high temperature environments. They may become loose or fall off, or even be completely deformed and cannot be restored.

Especially for systems used outdoors, in direct sunlight, or near heat sources (such as agricultural irrigation), it is necessary to pay more attention to the heat resistance of the pipe plug.

PVC plugs with unreasonable structures are often difficult to remove during daily maintenance or system overhaul, which is not only time-consuming and labor-intensive, but also easy to damage the pipe opening, causing secondary problems.

If the pipe network needs periodic inspection, the use of plug-in pipe plugs that are not easy to remove will greatly increase the operation and maintenance costs and affect efficiency.

The first step in selecting a pipe is to determine the pipe size. Be sure to check the standard size comparison table provided by the manufacturer to verify the matching degree between the inner and outer diameters of the pipe fittings and the selected pipe plugs.

Some users are used to installing by "feeling", and the result is that the plugs either cannot be inserted or are too loose and easy to fall off. Especially in industrial systems, irrigation projects, and other occasions with high strictness requirements, dimensional errors may directly lead to system failures.

PVC is not a single material. Its hardness, flexibility, and high temperature resistance vary greatly under different ratios.

If the application environment has factors such as high temperature, high pressure, strong sunlight, or chemical corrosion, it is recommended to use high-density PVC or reinforced composite materials to improve their anti-aging and pressure-bearing capacity. For general indoor drainage or decorative purposes, ordinary materials are sufficient.

Many plug problems are caused by brand mismatch and interface errors.

It is recommended to use the same brand of PVC plug as the original pipe, which will be more compatible in terms of interface shape, sealing, and durability. Not only will the installation be smoother, but it can also avoid loosening or leakage due to slight errors.

It may not be big, but it plays a big role. When buying a PVC plug, make sure that the size and material match your pipe, so as not to fail when it finally plays its role.