Industrielle ventiler are a crucial part of any piping system, responsible for regulating, directing, or controlling fluid, gas, and slurry flow within various industries. They can be found in power plants, chemical processing facilities, oil & gas operations, and water treatment plants, to name a few, and the right valve can significantly impact the performance, safety, and efficiency of your system.

This article will outline the 10 most common types of industrial pipes and valves, explain how they function, help you understand how industrial valves work, and what to look for when determining the best valve for your industrial application.

Founded in 2015 and headquartered in Zhejiang, China, PROCAMLOCK has rapidly become a trusted name in manufacturing camlock fittings, valves, filters, and fluid transfer systems. We serve a global customer base across key sectors such as petroleum, chemical, agriculture, and oil & gas industries.

To meet international quality and environmental standards, our products fully comply with global regulations and hold certifications.

These certifications enable our products' seamless integration into European og North American industrial systems.

EN ball valve is a quarter-turn valve with a simple yet effective design. Ball valves use a spherical hollow ball in the valve body to shut off flow. The ball rotates 90 degrees, or a quarter turn, from open to closed, allowing the valve to open and close quickly and provide a reliable shut-off.

EN Butterflyventil consists of a round disc on a rotating stem. When you turn the actuator, the stem rotates the disc from 0 to 90 degrees. At 0 degrees, the disc blocks any flow because it is perpendicular to the flow. At 90 degrees, it is also completely parallel to the flow, allowing for total flow. While these are simple valves, they also have precise flow control and can rapidly operate.

Kontraventiler are automatic valves used to prevent reverse flow in a pipeline. Most of them have a part that can be shifted (ball, disc, or piston), which is opened when the desired flow direction is present and closed when the flow direction is the opposite.

EN skydeventil is built with a plate or 'gate' rim that sits either parallel to the flow direction or at right angles to the flow direction. When it is in the fully opened position, the gate retracts into the valve bonnet, providing the full flow path. Closing occurs at the gate when the flow path is blocked by the gate coming down.

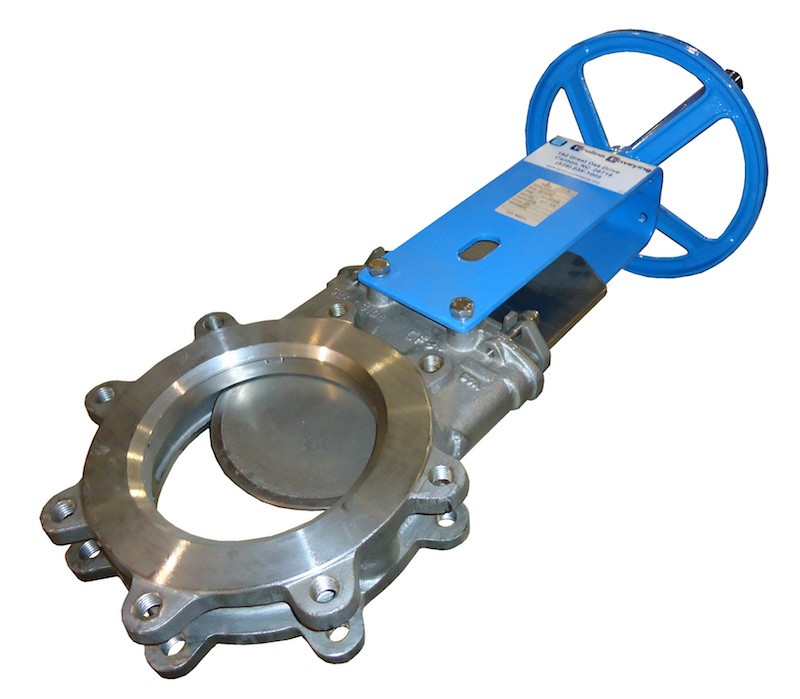

Knife gate valves have a flat, knife-like gate that fits into the flow to control or stop the flow. Gates are normally 3-25 mm thick, and gate motion is perpendicular to the flow. Pneumatic knife gate valves use compressed air (60-120 psi) to activate and enable speed of operation.

Globeventiler use a globular body with a movable round disc-type element and a fixed ring seat. The disc moves up and down at 90-degree angles to the seat, allowing for very accurate flow control. When turning the handwheel, the valve stem moves the disc toward or away from the seat, enabling precise flow regulation. Globe valves provide excellent throttling capacities.

EN needle valve is a specialized valve that contains a long, tapered needle-like disc. A needle valve is functionally similar to a globe valve and represents the linear motion family of valves, for which it can provide precise flow control. The design also allows for a greater degree of control in low-flow situations.

EN pinch valve consists of a flexible tube situated inside a valve body. Pinch valves function by "pinching" the tube using rollers, bars, and/or pneumatic actuators. As the tube is squeezed shut, it will gradually close to restrict flow over time. Once the tube is pinched and fully closed, the flow will be stopped.

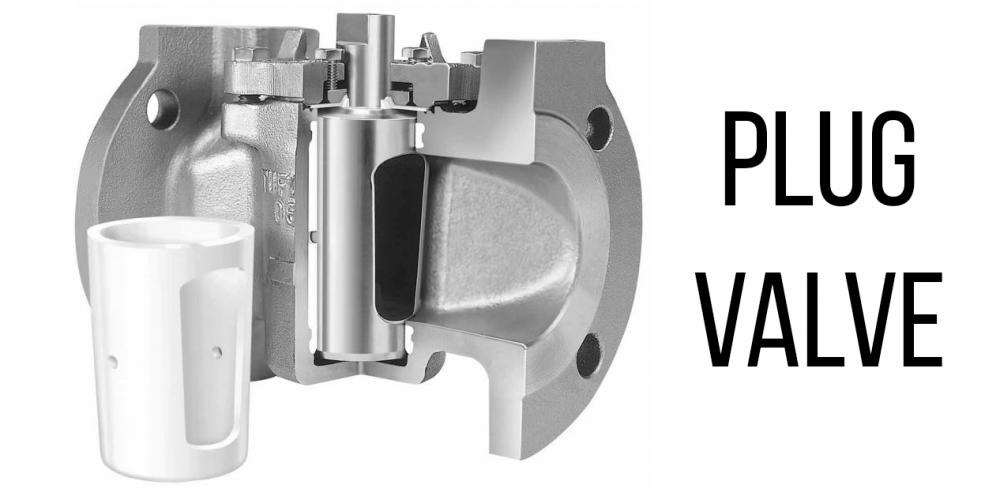

Plug valves utilize a tapered or cylindrical-shaped plug with a hole that rotates around its axis inside the valve body. When installed, the plug valve can accommodate flows by rotating the plug 90 degrees so the hole is aligned or misaligned with the inlet and outlet ports.

Pressure relief valves are a safety mechanism to protect against systems' overpressure. They consist of a spring-loaded disc on a seat. When system pressure builds above the spring force, the disc lifts, allowing fluid to escape to relieve pressure. Once the fluid pressure comes down below the set-point, the disc reseats.

Types of Valves | All in One Guide to Industrial Valve Types

| Valve Type | Design & Operation | Anvendelser | Key Materials | Fordele | Limitations |

| Kugleventil | Spherical disc with bore, quarter-turn operation | Pipelines, oil & gas, water treatment | Stainless steel, brass, PVC | Fast operation, tight seal, low pressure drop | Not suitable for throttling |

| Butterflyventil | Disc rotates on shaft, quarter-turn operation | HVAC, water treatment, large diameter pipelines | Cast iron, ductile iron, stainless steel | Compact design, quick operation, good throttling | Not suitable for high-pressure applications |

| Kontraventil | Self-operating, prevents backflow | Pump systems, water supply, oil & gas pipelines | Stainless steel, bronze, PVC | Automatic operation, quick response to flow reversal | Limited control over flow rates |

| Skydeventil | Flat/wedge-shaped gate moves perpendicular to flow | Water distribution, oil pipeline, power plants | Cast iron, steel, bronze | Excellent sealing, low pressure drop when fully open | Slow operations, not suitable for throttling |

| Knife Gate Valve | Knife-like gate cuts through media | Pulp & paper, wastewater, mining | Stainless steel, carbon steel, cast iron | Best for slurries, rapid operation with pneumatic actuation | Not suitable for high-pressure applications, possible safety risks |

| Kugleventil | Movable disc-type element, precise flow control | Steam system, power plants, chemical processing | Bronze, cast iron, stainless steel | Superior throttling, stable flow characteristics | Higher pressure drop compared to gate valves |

| Nåleventil | Long, tapered needle-like plunger for accurate control | Hydraulic/pneumatic systems, instrumentation, sampling | Stainless steel, brass, exotic alloys | Exceptional accuracy in flow control, high-pressure capability | Not suitable for high-flow applications |

| Pinch Valve | Flexible tube pinched to control flow | Mining, wastewater, food & beverage | Elastomers (rubber, EPDM, Viton) | Best for slurries and abrasive media, full-bore flow when open | Limited pressure ratings, periodic sleeve replacement |

| Plug Valve | Cylindrical/conical plug rotates to control flow | Oil & gas, petrochemical, wastewater treatment | Cast iron, carbon steel, stainless steel | Tight shutoff, low-pressure drop when fully open | Can be costly, may need high torque to operate |

| Pressure Relief Valve | Spring-loaded disc opens at set pressure | Boilers, pressure vessels, refineries | Stainless steel, bronze, cast iron | Rapid response to overpressure, reliable protection | Requires regular maintenance and testing |

Industrial valve standards serve as guidelines to ensure that the valves we use meet various industries' quality, safety, performance, and other requirements. Standards dictate all facets of valves, everything from design and material selection to pressure class ratings, dimensions, and how valves are tested.

Common valve standards include:

Using ITT industries valves compliant with recognized industrial valve standards for safety and performance will usually lead to better system reliability and safety. At the same time, the overall selection of complementary equipment ensures seamless integration into the end user's complex systems.

Proper industrial valve maintenance is important to achieve long service life, ensure safety and reliable operation, and contain system costs. Easy-to-maintain industrial valves routinely face high pressures, corrosive and abrasive substances, and extreme temperatures, so considering the potential for failure due to improperly maintained valves is vital to avoiding unnecessary downtime.

Recommended Maintenance Practices:

1. Regular visual inspection

2. Cleaning and lubrication

3. Replacement of seals and gaskets

4. Actuator checks

5. Documentation and maintenance schedule

Regular industrial valve repairs and care will ensure improved system performance, comply with industrial safety standards and regulations, and promote uptime and reliability.

Choosing the best type of valve is important to the reliability and efficiency of the system. Each has specific characteristics; for example, ball valves are known for fast opening, and globe valves can have precise control. However, there are particular requirements of your application that you should consider when making your decision, including pressure, flow characteristics, and temperature.

Do you want help choosing the right valve to suit your system? Contact us for expert guidance and explore our range of high-quality valves tailored to your technical requirements.

EN: A safety valve is a specialized valve that protects pressure vessels, piping systems, and other equipment from overpressure conditions.

EN: A pressure-reducing valve, or a pressure regulator, works by lowering the fluid's pressure from a higher inlet pressure to a constant and lower outlet pressure.

EN: Valve type testing is a process of examination of the valve type to ensure that it has been constructed to the required standards of reliability, performance and safety.

EN: Valve design testing ensures valves are safe, perform well, and are reliable through rigorous testing.