الصمامات الصناعية وتجهيزات الكالموك بالغة الأهمية في أنظمة الغاز والسوائل. فهي تتحكم في تدفق السوائل أو الغاز، بينما تُسهّل تجهيزات الكالموك توصيل وفصل الأنابيب والأجهزة الأخرى بانتظام.

تساعد الصمامات والتجهيزات على انسيابية التدفق، وضمان السلامة، وتنظيم كمية وضغط المياه، وتوفير التحويلات. كما يضمن استخدام الصمامات الصناعية المناسبة وتجهيزات الكامات في أنابيبكم كفاءة النظام ويقلل من وقت التوقف.

هناك طلب متزايد على مختلف الصمامات الصناعية وتجهيزات الكامات. هنا، ستتعرف على المزيد عنها، وأنواعها، وتطبيقاتها، وأماكن شرائها في المملكة المتحدة.

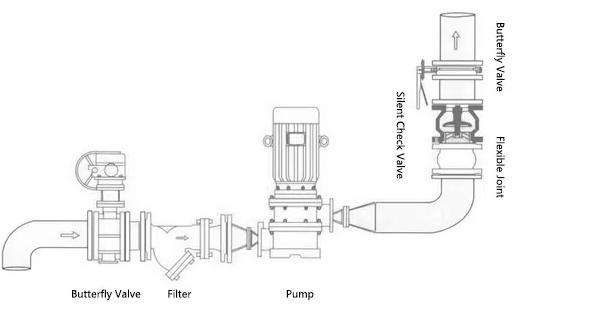

تتكون أنظمة توصيل السوائل أو الغازات من أجزاء مثل الأنابيب، والموصلات، ووحدات التخزين، والصمامات. تعمل جميع هذه الأجزاء معًا لتوصيل المحتوى بالكميات والضغط المناسبين إلى الوجهة المستهدفة. تلعب الصمامات الصناعية وتركيبات الكامات دورًا هامًا في هذا النظام.

إذن، ما هي الصمامات الصناعية وتجهيزات الكامات، وما هي فوائد استخدامها معًا في نظام واحد؟

تتحكم الصمامات الصناعية في تدفق الغاز والسوائل عبر خطوط التوصيل أو التخزين. واعتمادًا على تصميم الصمام، يمكنها فتح أو إغلاق أو تنظيم التدفق.

تجهيزات قفل كاملوكتُعرف أيضًا بوصلات الكامة والأخدود، وهي تسمح بالتوصيل والفصل السريع. تتكون الوصلة سريعة التوصيل من قابس ذكر أو محول يُركب في مقبس أو وصلة أنثى. يُقفل كلاهما معًا باستخدام رافعة بسيطة، مما يُنشئ اتصالًا مانعًا للتسرب بين الخراطيم أو الأجهزة الأخرى.

هناك العديد من أنواع الصمامات الصناعيةتختلف الصمامات من حيث الأنواع والوظائف ومعدلات الضغط والحجم وطريقة التشغيل والمادة. يشير معدل الضغط إلى أقصى ضغط يمكن أن يتحمله الصمام دون تلف.

فيما يلي بعض الصمامات الصناعية الأكثر شيوعًا المستخدمة في الصناعات المختلفة.

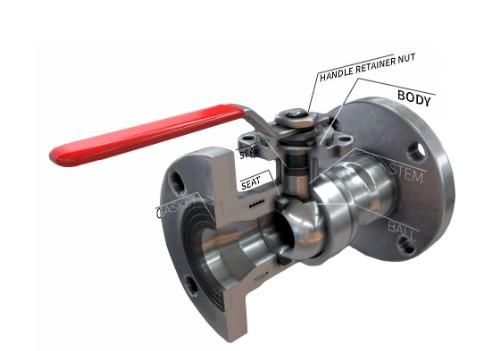

صمام الكرة هو صمام صناعي يستخدم كرةً لإغلاق أو فتح وتنظيم التدفق في خط الأنابيب. يتميز الصمام بانخفاض ضغط ضئيل وزمن استجابة منخفض جدًا. تُعد صمامات الكرة مثالية لفتح وإغلاق خط الأنابيب بسرعة. كما أنها تدعم التشغيل اليدوي والهوائي والكهربائي.

يحتوي المجال الداخلي للصمام على ثقب مروري قطره مساوٍ لقطر الأنبوب المُثبّت. عند فتحه، يصطف الثقب مع الأنبوب، مما يوفر فتحةً كاملةً دون أي قيود على تدفق السائل.

تساعد تصاميم صمامات الكرة على التحكم في السوائل والغازات عالية الضغط. وتغطي تطبيقاتها قطاعات متنوعة، من الاستخدام السكني إلى مختلف الصناعات.

من مزايا صمامات الكرة أيضًا توفرها بمواد متنوعة لدعم استخدامها مع مواد مختلفة. المواد الأساسية المستخدمة في صناعة صمامات الكرة الصناعية هي:

صمام الفحص هو صمام مانع للرجوع، أو صمام قائم، أو صمام أحادي الاتجاه، يسمح بتدفق السائل في اتجاه واحد فقط. وهو صمام ذو منفذين، بفتحتين على جسمه: مدخل ومخرج.

يمنع تصميم هذا الصمام الصناعي اللارجعي التدفقَ العكسي للسوائل في الأنابيب. ويضمن تدفقًا أحادي الاتجاه للوسط داخل النظام. يستخدم صمام الفحص آليةً تسمح بمرور السوائل تحت الضغط. عند إغلاق مدخل الأنبوب، يُغلق صمام الفحص التدفقَ العكسي لأنبوب المخرج تلقائيًا.

المجالات الرئيسية لتطبيق وفوائد صمامات الفحص هي:

صمام الفحص الأكثر شيوعًا يستخدم النحاس، على الرغم من أنه يمكنك العثور على صمامات رجوع مصنوعة من مواد أخرى.

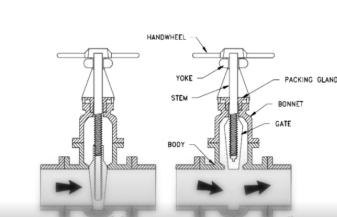

الوظيفة الأساسية لصمام البوابة هي الإغلاق الكامل أو الفتح الكامل. لا يُستخدم صمام البوابة للتحكم في كميات التوصيل. صمامات البوابة قياسية لفتح وإغلاق خطوط الأنابيب بشكل غير منتظم.

يعمل صمام البوابة عن طريق تثبيت صفيحة تشبه البوابة على طول مسار السائل. يفتح ويغلق بحركة خطية رأسية. يستخدم الصمام نظامًا ملولبًا يربط المشغل بنظام البوابة.

صمام بوابة جذعية غير صاعدة مغلقة ومفتوحة

نظرًا لعدم انسداد صمام البوابة وانخفاض فقدان الضغط، فهو مثالي لمنافذ تنظيف الأنابيب أو الخزانات. كما أنه مناسب لإغلاق الأنابيب أثناء الصيانة والإصلاحات أو عند تغيير اتجاه التدفق.

المواد الشائعة المستخدمة في صمامات البوابة هي:

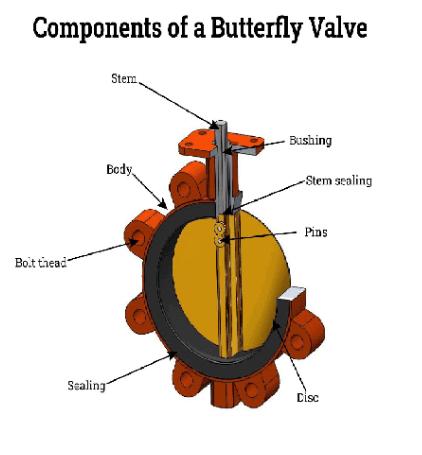

صمام الفراشة هو صمام حركة دورانية ربع دورة، يُوقف تدفق المياه في الأنابيب. يستخدم قرصًا يدور بزاوية 90 درجة في مركز فتحة الأنبوب.

تعتمد صمامات الفراشة على مبدأ عمل بسيط نسبيًا. عند إغلاقها، يسد القرص تجويف الصمام. ويصطف القرص عموديًا على الأنابيب في وضع الفتح، مما يسمح بالتدفق.

لأن صمامات الفراشة ليست كاملة التجويف، فهي غير مناسبة للتنظيف بالفرشاة أو المسح. كما أن قرص الصمام يُقيد التدفق، مما يُسبب انخفاض الضغط.

صمامات الفراشة مثالية للأنظمة ذات السعة الكبيرة. فهي أخف وزنًا بكثير من صمامات الكرة ذات أقطار الأنابيب الكبيرة، وتتطلب مساحة تركيب أصغر. ومن الأمثلة الجيدة على تطبيقاتها صمامات الفراشة المستخدمة في محطة معالجة مياه نهر التايمز.

المادة القياسية لجسم صمامات الفراشة هي الحديد المطاوع، والذي يتم طلائه بالإيبوكسي على الأسطح الداخلية والخارجية.

الفوائد الرئيسية لصمام الفراشة هي:

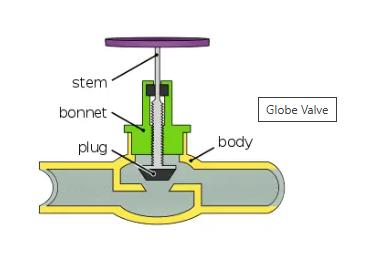

صمام الكرة ليس صمامًا ذا مسار مستقيم، بل يُشتق اسمه من شكله الأسطواني. يُمكن للصمام إغلاقه والتحكم في تدفق السوائل في الأنابيب.

يحتوي الصمام على حاجز داخلي، مع مدخل ومخرج لتدفق المواد. تصميمه يمنحه انخفاض ضغط أعلى من صمامات الكرة والبوابة.

عند الحاجة، يُستخدم صمام الكرة في العديد من الصناعات التحويلية. يُستخدم بشكل أساسي في صنابير المياه البسيطة. كما يُستخدم في صناعة أنابيب المصانع. يتوفر صمام الكرة يدويًا أو آليًا. هذه الصمامات قادرة على تنظيم الضغط والتحكم في التدفق.

نظرًا لشكلها المعقد، تُصنع صمامات الكرة من المعدن المصبوب. ومع ذلك، يستخدم بعض مصنعي الصمامات الصناعية موادًا مطروقة لتصنيع صمامات الكرة حسب الطلب.

يُستخدم البرونز في صناعة حلقات قرص الصمام ومقعده. كما يُقدم مُورِّدو الصمامات الصناعية صمامات كروية من الفولاذ المقاوم للصدأ للعمل في درجات حرارة تتجاوز 350 درجة مئوية. كما تُستخدم سبائك الكوبالت في تصنيع صمامات الكرات.

وصلات الكالموك هي شكل موحد لوصلات الخراطيم والأنابيب. لها طرفان، أحدهما ذكر والآخر أنثى، يُقفلان معًا بنظام مانع للتسرب باستخدام رافعات يدوية.

تأتي تجهيزات الكالموك بأنواع مختلفة ومصنوعة من مجموعة واسعة من المواد.

هناك عدة تكوينات تصميمية لتركيبات قفل الكامات. يستخدم كل تصميم تسمية حرفية (من A إلى F، DC، DP). تُسهّل هذه الأحرف عملية التحديد ومطابقة التطبيقات. فيما يلي شرح لأنواع قفل الكامات:

| يكتب | ميزات التصميم |

| أ | محول ذكر وخيط أنثى |

| ب | محول أنثى وخيط ذكر |

| ج | ساق خرطوم ومحول أنثى |

| د | وصلة أنثوية وخيط أنثوي |

| هـ | ساق خرطوم ومحول ذكر |

| ف | محول ذكر وخيط ذكر |

| دي سي | غطاء غبار لتغطية المحولات |

| دي بي | سدادة غبار للاستخدام مع الوصلات |

تلعب المواد دورًا حاسمًا في أداء وصلات الكالموك وملاءمتها. تُحدد المادة البيئة والمادة. فيما يلي المواد الأكثر شيوعًا المستخدمة في تصنيع وصلات الكالموك:

تتميز وصلات كام لوك بمزايا عديدة، مما يجعلها الخيار الأمثل في العديد من التطبيقات الصناعية. تتيح أدوات التوصيل هذه توصيلات وفصلات سريعة للخراطيم دون الحاجة إلى أدوات. مزايا تجهيزات الكالملوك نكون:

فيما يلي الصمامات الصناعية وتجهيزات الكامات من الموردين الموثوق بهم في المملكة المتحدة وعلى الصعيد العالمي.

شركة تصنيع عريق، تتميز بالابتكار المستمر، تخدم أكثر من 140 دولة. حاصلة على شهادة ISO9001:2008، وتتخصص في:

تتمتع الشركة بخبرة إنتاجية تزيد عن 135 عامًا. وتقدم منتجات مبتكرة مثل قفل ECHO NFC الذي يعمل بدون بطارية ونظام Omnis عالي الأمان. ومن أهم منتجات لو آند فليتشر:

شركة صينية المنشأ، تتمتع بخبرة 40 عامًا في إنتاج مكونات تكنولوجيا السوائل. تلتزم الشركة بالمعايير الدولية مثل ISO9001 وISO14001 وCE وOHSAS18001 في منتجاتها، مثل:

بروكاملوك شركة رائدة في تصنيع تجهيزات كاملوك وحلول نقل السوائل المتقدمة. تقدم خدمات شاملة تشمل التصميم حسب الطلب، والصب الدقيق، والتشغيل الآلي باستخدام الحاسب الآلي، والتجميع. تضمن قدراتها الداخلية، مثل ورشة عمل متخصصة لنماذج الشمع وعملية غمس متقدمة، منتجات عالية الأداء ومقاومة للتآكل، مصممة خصيصًا لتلبية مختلف الاحتياجات الصناعية.

تلتزم شركة بروكاملوك بالجودة والابتكار والخدمة العالمية، وتلتزم بمعايير ISO 9001 وISO 14001 وISO 45001 الصارمة في كل مرحلة من مراحل الإنتاج. تشمل منتجاتها الرئيسية ما يلي:

تأسست الشركة عام ١٩٨١، وهي متخصصة في تركيبات الكامات المصممة بدقة. منتجاتها تلبي متطلبات ايزو 9001 المعيار وتوجيه معدات الضغط 97/23/EC. منتجات ديكسون الرئيسية هي:

من الضروري اختيار الصمام الصناعي المناسب مع وصلة قفل كام لوك فعّالة. يجب اختيار الصمام الصناعي المناسب للتحكم في التدفق وتنظيم الضغط، وينطبق الأمر نفسه على وصلات قفل كام لوك.

عند شراء صمام صناعي أو وصلة كاملوك، احصل على منتجاتك من موردين موثوقين ومعتمدين. ستحصل على منتجات عالية الجودة، وسيقدمون لك نصائح حول المادة المناسبة لعملك. كما يُنصح بالتحقق من سمعة الشركة المصنعة للصمامات الصناعية من خلال تقييمات العملاء السابقين.

يمكنك تنزيل ملفنا دليل المنتج لاستكشاف مجموعتنا الواسعة من الصمامات الصناعية ووصلات الكامات. يمكنك أيضًا التواصل مع خبرائنا لأي استفسارات أو للحصول على نصائح حول الصمام الصناعي أو وصلة الكامات المناسبة لنظامك.

1. ما هي أكثر أنواع الصمامات الصناعية شيوعًا المستخدمة في مصانع التصنيع والمعالجة؟

تشمل الأنواع الأكثر شيوعًا صمامات الكرة، وصمامات البوابة، وصمامات الكرة الأرضية، وصمامات الفراشة. صُممت كل منها للتحكم في التدفق في بيئات صناعية محددة.

2. كيف تعمل تجهيزات Camlock في توصيلات الخراطيم ذات الضغط العالي؟

تستخدم وصلات الكامات أذرع الكامات لتثبيت الخراطيم معًا بإحكام. وبالتالي، تُشكّل سدادة مانعة للتسرب، مثالية للتوصيلات السريعة في تطبيقات الضغط العالي.

3. ما هو الفرق بين صمامات الكرة وصمامات البوابة في التطبيقات الصناعية؟

توفر صمامات الكرة إغلاقًا سريعًا بربع دورة، بينما توفر صمامات البوابة تحكمًا أبطأ في التدفق بشكل خطي. وكلاهما مناسب لاحتياجات إدارة التدفق المختلفة.

4. ما هي أفضل المواد المستخدمة في تركيبات Camlock المستخدمة في أنظمة نقل المواد الكيميائية؟

تُستخدم تجهيزات Camlock المصنوعة من الفولاذ المقاوم للصدأ والبولي بروبيلين بشكل شائع في التطبيقات الكيميائية بسبب مقاومتها للتآكل ومتانتها.

5. أين يمكنني شراء صمامات صناعية عالية الجودة وتجهيزات Camlock عبر الإنترنت؟

من بين الموردين الموثوقين عبر الإنترنت: Camlock Systems Ltd، وLowe & Fletcher Ltd، وProCamlock. جميعهم يقدمون مجموعة واسعة من المكونات الصناعية عبر الإنترنت.

6. كيفية تركيب وصيانة تجهيزات Camlock للاستخدام الصناعي على المدى الطويل؟

تأكد من المحاذاة الصحيحة، وتأمين أذرع الكاميرا بإحكام، وفحص الأختام بانتظام للحفاظ على الأداء ومنع التسربات أو التآكل.